Nazanin Minaian

Ph.D. in Mechanical Engineering | Research Faculty

University of Nevada, Las Vegas

Active Materials and Smart Living (AMSL) Lab

Biography

Nazanin Minaian, Ph.D., is a mechanical engineer and researcher specializing in bio-inspired sensing systems and smart materials. She earned her doctorate in Mechanical Engineering from the University of Nevada, Las Vegas, where her research in the Active Materials and Smart Living (AMSL) Lab focused on electroactive polymers (EAPs) for flow sensing and energy harvesting. Drawing inspiration from aquatic sensory organs, she developed polymer-based “artificial skin” and canal-type sensors capable of detecting fluid dynamics in complex environments. Her work bridges materials science, fluid mechanics, and biomimetic design to advance technologies for underwater robotics, renewable energy, and soft sensing platforms.

In addition to her research, Nazanin is committed to mentorship and scientific community building. She has guided undergraduate and graduate students through interdisciplinary projects in smart materials and experimental design, fostering curiosity, technical skill, and creative confidence in emerging engineers. As an Iranian-American engineer, she is passionate about cross-disciplinary collaboration and inclusive innovation that connects natural principles with human-centered technology.

- Electroactive Polymers (EAP)

- Imaging and Image Processing

- Bio-Inspired Robotic Designs

PhD in Mechanical Engineering, 2025

University of Nevada, Las Vegas

MS in Aerospace Engineering, 2024

University of Nevada, Las Vegas

BS in Mechanical Engineering, 2018

University of Nevada, Las Vegas

Skills

Python, Jupyter, MATLAB, Wolfram Mathematica

SolidWorks, COMSOL Multiphysics, Autodesk Fusion 360 Simpleware ScanIP

SEM, FFT Analysis, Additive Manufacturing, Laser Cutting, DMA

DSLR, PIV (Planar and Volume), Motion Tracking

Project Reports, SOPs, Proposals, Conference Posters/Presentations, Publications

Adobe Suite, LabView, VSCode

Experience

Active Materials and Smart Living (AMSL) Lab

Responsibilities include:

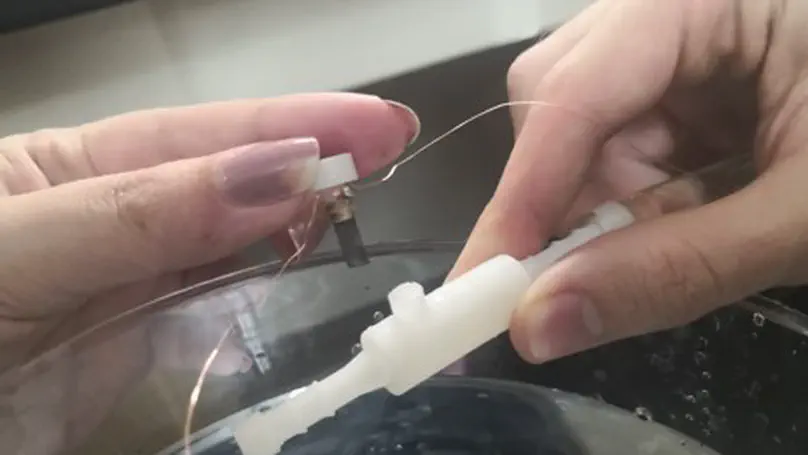

- Researched electroactive polymers (EAPs), focusing on ionic polymer-metal composites (IPMCs) and their use as flexible fluid flow sensors for naval and underwater applications.

- Communicated directly with multiple vendors for acquiring and configuring substantial equipment related to the experimental setup for ONR Grant N00014-16-1-2356.

- Modeled with CAD software and utilized additive manufacturing for experimental testing platforms.

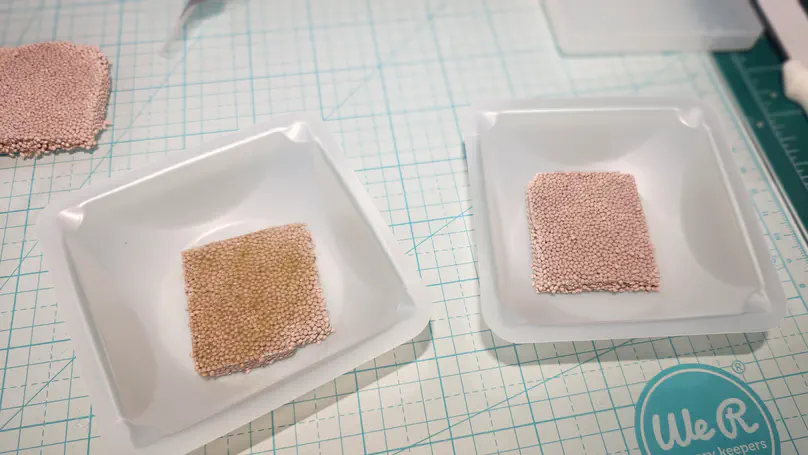

- Fabricated EAP actuators and sensors in a wet laboratory environment for applications in soft robotics and flow sensing.

- Developed physics-based models using COMSOL software for fluid-structure interaction studies, and vortex shedding for a MEMS vortex flowmeter.

- Design of experiments and data acquisition for various EAP actuators and sensors.

- Utilized various imaging and image processing techniques; including the development of a computer vision-based software in Wolfram Mathematica for tracking sensor deflection, travel velocity, and vortex shedding.

- Lead on Particle Imaging Velocimetry (PIV) equipment attainment and setup. Wrote Standard Operating Procedure and implemented safety protocols for use.

Soft Mechatronics (SM) & Robotics Lab

Responsibilities include:

- Collaborated with a multinational team in South Korea researching soft-robotics and artificial muscles at the Korea Advanced Institute of Science and Technology (NSF Grant #1545857).

- Fabricated and modeled a piezoelectric energy harvesting ring-type transducer comprised of a PVDF film supported by a PDMS substrate

- Fabricated EAP actuators and sensors in a wet laboratory environment for applications in soft robotics and flow sensing.

- Designed and assembled a testing apparatus for the energy harvester ring, along with a fingerbending model using additive manufacturing and laser cutting.

Projects

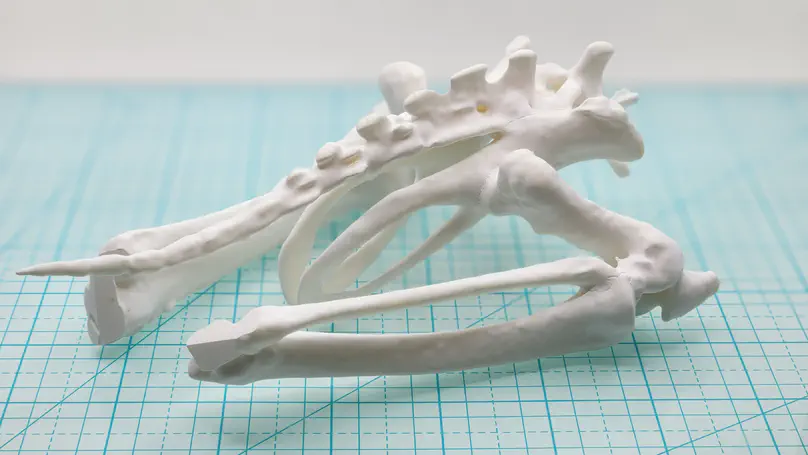

Utilizing acquired DICOM images to create CAD models designed for additive manufacturing (employing various software suites such as Simpleware ScanIP and Autodesk Fusion 360). This project is an ongoing effort in gaining insight into new working mechanisms that will aid in underwater vehicle or platform design – largely inspired by biological components. Currently the lead on this project to create a scalable Sea Lion pelvis model that can be used for training volunteers on blood extraction. Additionally mentored two undergraduate students as a technical advisor who utilized this method for their university capstone project.

Submitted proposal on anti-fouling methods for proprietary company surface coating materials was presented at a symposium by local startup company. Was selected as the top pick for funding from a group of graduate-level researchers at UNLV. Collaborated and researched methods to further improve thermal and anti-fouling characteristics of proprietary surface coating material.

Designed a small-scale vortex flow meter with an interior diameter of 10 mm and implemented a 5 mm rectangular IPMC sensor to detect the frequency of vortices shedding from a bluff body. SLA printed and wired fully functional prototype. Performed COMSOL fluidstructure analysis to verify acquired experimental data.

Lead on managing the fluid dynamics division of the Active Materials and Smart Living (AMSL) lab within UNLV. Tasks include procurement of equipment and negotiating with the university regarding competitive exemption of equipment purchasing; Equipment includes but not limited to a Loligo® Systems Swim Tunnel (185L), TSI V3V Particle Imaging Velocimetry (PIV) System, and a three-phase VFD which required additional electrical setup per university building requirements; Responsible for decisions on equipment location, operation, and was lead on installation; A standard operating procedure (SOP) was written and approved along with extensive safety considerations and training plans as required from the building where the lab resides; A safety enclosure was also designed and fabricated to meet safety guidelines.

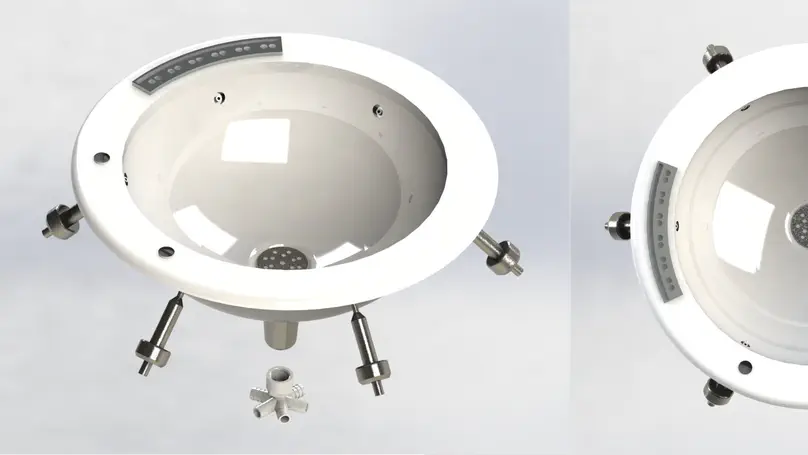

Concepted, designed, and fabricated a novel faucet-less sink with multiple radially placed laminar nozzles within the sink basin to provide unobstructed hand and face washing capabilities. Focused on CAD modeling, fluid dynamic analysis, material selection, fabrication, marketing, and dissemination of results. Awarded 1st Place Interdisciplinary Engineering Design Award Spring 2018

Recent Publications

Popular Topics

Contact

- nazanin.minaian@gmail.com

- (702) 744-7082

- 4505 S Maryland Pkwy, Las Vegas, NV 89154

- Office 2173 - Please request permission from downstairs help desk to visit 2nd floor.